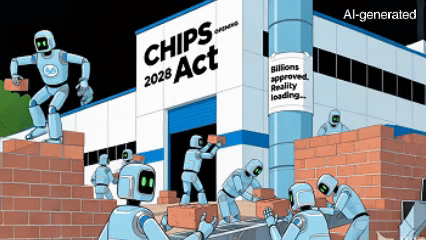

Trillions in investment have been announced in a bold promise to revive America’s manufacturing sector. From car factories 🚗 to aluminum smelters, the idea is to restore a crucial part of the industrial backbone. But here’s the reality check: building these state-of-the-art facilities is anything but quick.

Experts, including economist Erin McLaughlin from the Conference Board as cited by the Financial Times, highlight that projects of this scale typically take three years or more to become operational. From selecting a site and securing permits to designing facilities, constructing the plant, and sourcing advanced machinery, every step requires time and precision.

For our tech-savvy readers in bustling cities like Bangalore, Jakarta, or Ho Chi Minh City, this is a familiar vibe – where big ideas and massive investments often need years of groundwork before you see the final magic. It’s a clear reminder that even in an era of rapid change, some transformations are a marathon, not a sprint. 💡

This piece is part II of a series by CGTN that uses AI-generated GIFs to unpack the real-world outcomes of America’s industrial revival efforts. While the headlines boast of trillions in investment, the tangible impacts will only unfold over time.

Reference(s):

cgtn.com